BHP MCC16/31 VSD Upgrade

BHP MCC16/31 VSD Upgrade Mt Arthur Coal

We’re proud to announce that AVE Technologies has won the 2025 NECA NSW Excellence Award in the Small Industrial Project category for our work on the BHP MCC16/31 VSD Upgrade project at Mt Arthur Coal.

This award recognises our team’s technical expertise, innovation, and commitment to delivering outstanding results on complex industrial projects.

Project Overview

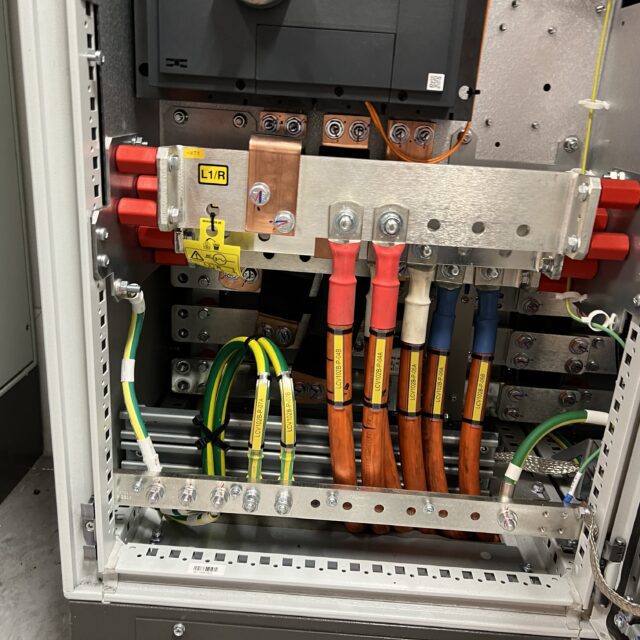

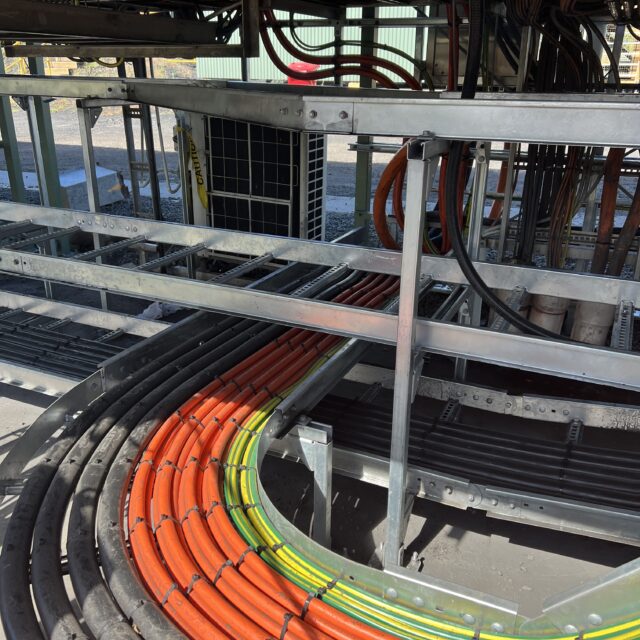

The MCC16/31 VSD Upgrade for BHP began with an initial review of the electrical design for compliance with site standards and buildability. The original scope involved replacing five Fuji Frenic 5000 VSDs with five Schneider Altivar 980 VSDs across two conveyors in the existing switchroom.

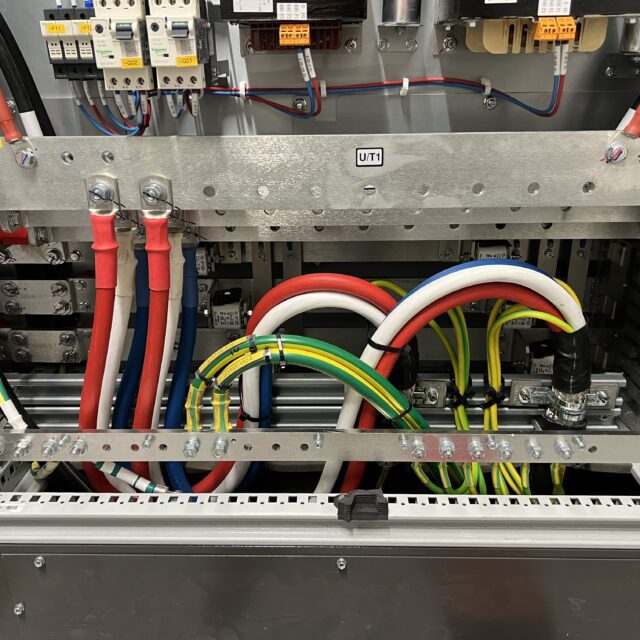

Following a joint design review and risk assessment with the client, the project scope was revised to include a new switchroom pre-fitted with the VSDs and Fan Motor Control Centre. This was built off-site and later integrated on-site, significantly reducing manual handling risks and minimising future downtime during change-outs.

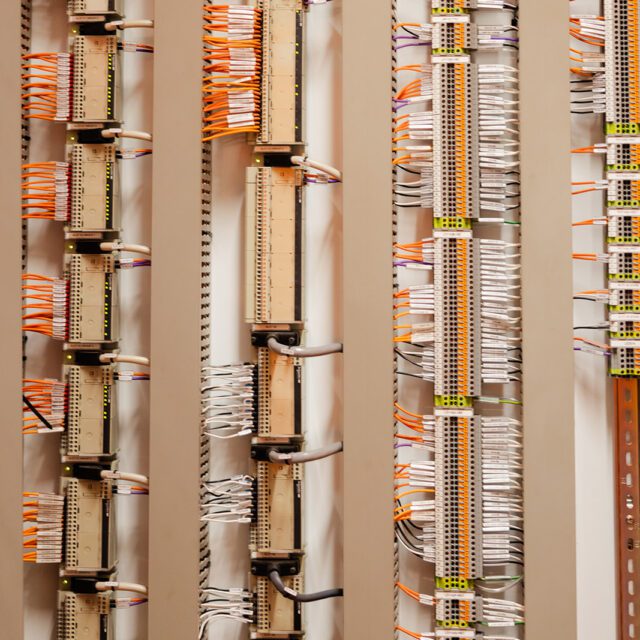

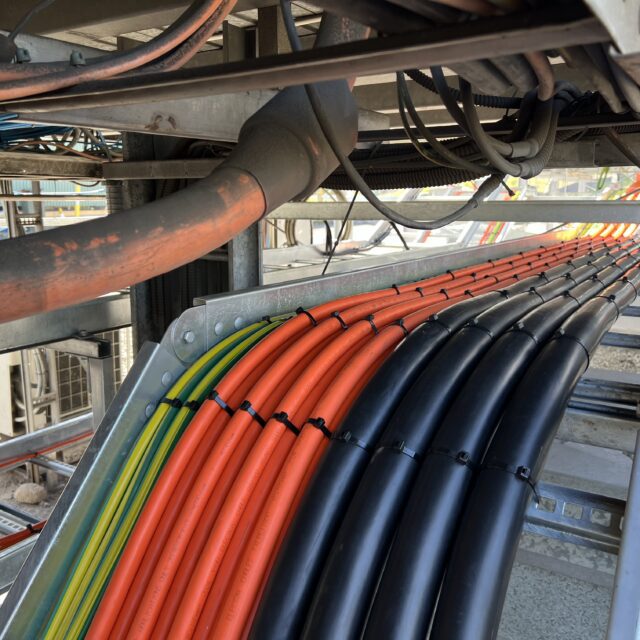

AVE Technologies provided Owners Team Engineering Support during redesign, and was awarded the Electrical Installation and Commissioning contract. Our scope included supplying and installing the Motor Control Centre, PLC equipment, cable ladder, and cables, with work carried out in multiple phases, including pre-work, two major outages, and the staged removal of redundant equipment.

The final major outage was completed successfully in February 2025, with commissioning finalised within three shifts instead of the allocated four.

Key Challenges & Solutions

Commercial Pressures:

The client’s decision to adopt a new switchroom introduced an additional $1M in project costs. While this was outside the original scope, AVE supported the redesign and managed resources to ensure the change did not delay delivery. By integrating the switchroom, we eliminated manual handling risks and reduced future downtime during change-outs—safeguarding production continuity and long-term value for the client.

Site Complexity:

Our team implemented a structured pull sheet process, detailed document control, and efficient cable management systems to maintain progress. In addition, we developed a comprehensive commissioning plan that covers termination and testing documentation, all of which is digitised on tablets to prevent delays and lost records. Collaboration was critical—AVE worked closely with the client, designers, contractors, and OEMs to coordinate every aspect of delivery. Using our SharePoint site as a central hub, we managed live registers for issues, actions, risks, and punchlists—later adopted by BHP as their project closeout framework. This structured, collaborative approach ensured the project remained on track and nothing was overlooked.

Unforeseen Constraints:

Wet commissioning was delayed due to concurrent works, necessitating 24-hour support. Our dedicated team managed workload fluctuations by reallocating resources to ensure critical deadlines were met.

Sustainability Focus:

By reusing existing cables and infrastructure wherever possible, we minimised waste, reduced environmental impacts, and delivered long-term efficiency gains with newer, more reliable equipment.

Innovation & Technical Excellence

We showcased innovation and technical excellence by developing and implementing a cable pull sheet process that enhanced accuracy and efficiency across the project. By leveraging digital document control systems, we streamlined delivery and enhanced project oversight. Our team also introduced newer, energy-efficient equipment that significantly reduced lifetime operating costs, while maintaining rigorous safety and compliance standards- even in the most challenging site conditions.

Training & Team Development

This project also served as a strong platform for developing our people. Apprentices were actively involved, gaining valuable on-site experience that accelerated their learning. Team members embraced increased responsibility, supported through structured mentoring that strengthened capability across the board. One emerging team member took a significant step forward by successfully compiling the commissioning package, highlighting both career growth and leadership development opportunities within our team.

Outcomes

The MCC16/31 VSD Upgrade was delivered safely, on time, and within the revised budget. The project has reinforced AVE Technologies’ reputation as a trusted partner for complex industrial projects and has already led to further opportunities with BHP, as well as strengthened relationships with key suppliers, including Schneider and TLE.

Award Recognition

Winning the 2025 NECA NSW Excellence Award for Small Industrial Project is a testament to the dedication and innovation of our people. We are honoured to be recognised by our industry peers and remain committed to delivering solutions that combine technical excellence, sustainability, and long-term value for our clients.

Thank you for the successful completion of the CHPP VSD Upgrade Project. This project involved the upgrade and integration of new Variable Speed Drives (VSD) at Mt Arthur’s coal handling and preparation plant (CHPP), and had a strong emphasis on safety, ensuring electrical reliability, minimizing disruption and de-risking future export coal handing operations.

– Daniel Lane (Project Manager, Engineering Projects – Mt Arthur Coal)

AVE Technologies is one of the largest multi-faceted electrotechnology companies in NSW. We have a team of over 70 employees, including specialists in each field, who can collaborate to provide a comprehensive, integrated solution for any project.

From small business phone and CCTV systems to large-scale, fully integrated technology projects for various industries like financial institutions, schools and universities, mining sites, sporting clubs and government facilities – we do it all!

Incorporating Electrical, Data Cabling, Control Systems, Audio Visual, Security Cameras & CCTV, Intercom Systems, Operational Technology, PA Systems, Telephone Systems, MATV and Excavator and Plant GPS Systems.

Don’t hesitate to get in touch if you have any questions or need help planning your next project!